Pt100 and Pt1000

temperature sensors

PT sensors are in the category of temperature sensors pursuant to ČSN EN 60751, where a platinum resistance layer is vapour deposited on a ceramic substrate. The connecting wires are welded to the platinum layer. To attach the wires and relieve their tensile stress, another glass layer is applied. The PT sensors are available in various versions PT100, PT500, PT1000. They have small dimensions, a higher accuracy, and a quick response time.

areas of use

Pt100 and Pt1000 sensors

Platinum sensors are designated according to the resistance value in Ω at a temperature of 0°C in the R0 resistance values. Accordingly, the PT100 sensor has resistance of 100 Ω, the PT500 sensor has resistance of 500 Ω, the PT1000 sensor has resistance of 1 kΩ, etc. However, the most frequent types are PT100 and PT1000 and, according to the international recommendations under IEC 751, they are divided into two tolerance classes: A (from -200°C to +650°C) and B (from -200°C to +850°C).

One of the characteristics of resistance temperature sensors is the temperature coefficient TCR. It is defined as a mean relative change of resistance per degree Celsius between temperatures from 0°C to 100°C, and is typically given as TCR = 3,850 ppm/°C.

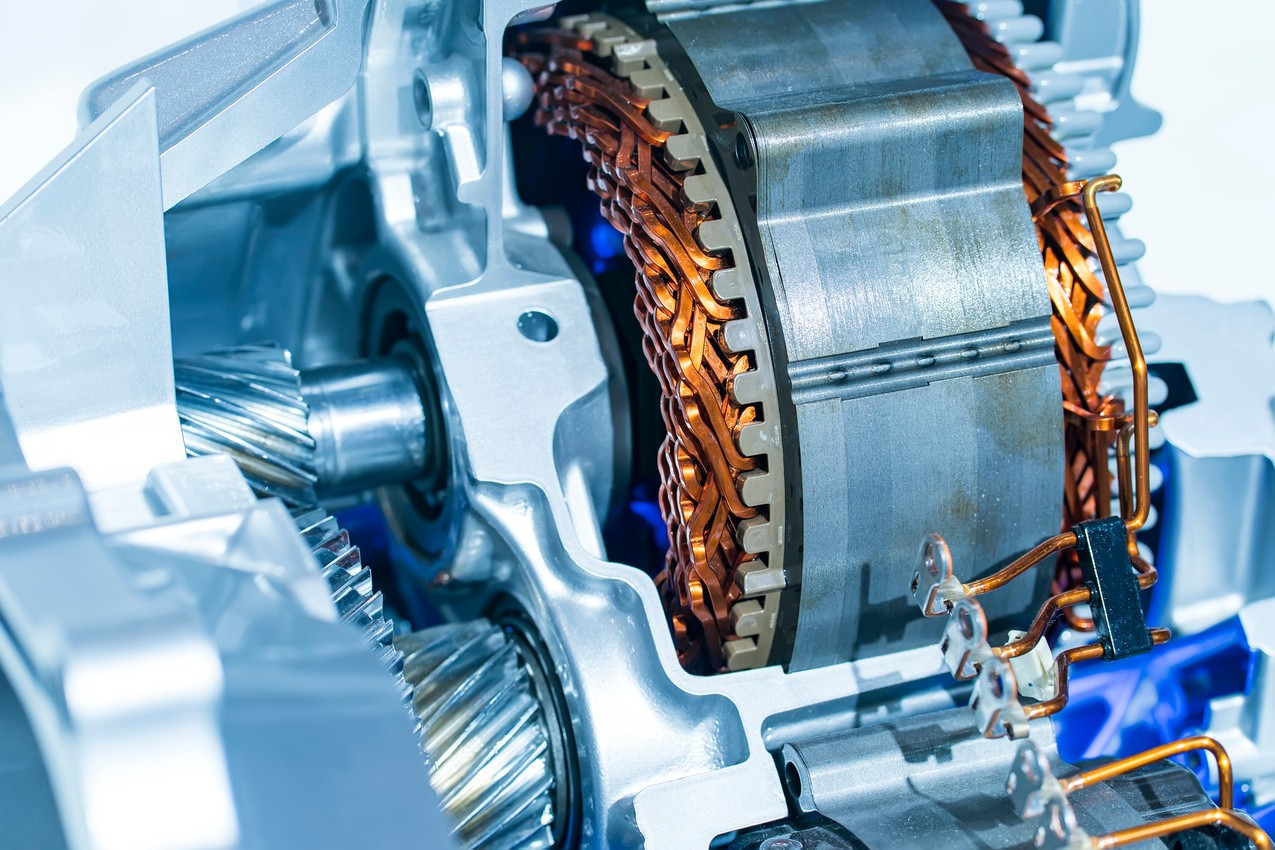

PT sensors are used in various areas, in particular in HVAC, medical and laboratory equipment, instrumentation and control, and automotive. We focus on manufacturing sensors designed as temperature sensors for windings of electric motors and transformers where they are connected to the sensor itself using a suitable method (mostly by soldering), the connecting wires and the sensor body together with connected wires are insulated with a shrinkable tube, mostly in two layers to achieve an adequate electric strength.

we focus on

- manufacturing ready-made products with PT 100, PT 500 and PT 1000 sensors

- testing breakdown voltage

- measuring RT characteristics

- individual solutions of the sensor design, lead wires, and insulation

Bc. Jan Kovář